2026-01-16 Shenzhen Linx Technology Co.,Ltd 0

Today, the Lirinx Technology park in Huizhou welcomed a group of familiar guests - the core quality control (QC) team from a well-known Japanese listed company. This is the team's second dedicated visit within two months. Unlike the initial preliminary understanding, this visit is a comprehensive, penetrating, and in-depth review and communication from the research and development source to the production end. This marks that the cooperation between the two parties has moved from the initial contact to a substantive new stage based on deep mutual trust and professional resonance.

From the Laboratory to the Production Line: A "Panoramic" Professional Dialogue

The visit was highly intensive and in-depth. The Japanese QC team first arrived at Lilingxin's Shenzhen R&D center and did not merely listen to reports; instead, they directly got involved in the front-end of product development. They conducted a detailed review of the new product acoustic design plans in the pre-research stage, the component selection verification reports, and the reliability test standard library. They also engaged in technical discussions with Lilingxin's engineering team for several hours regarding multiple test methodologies.

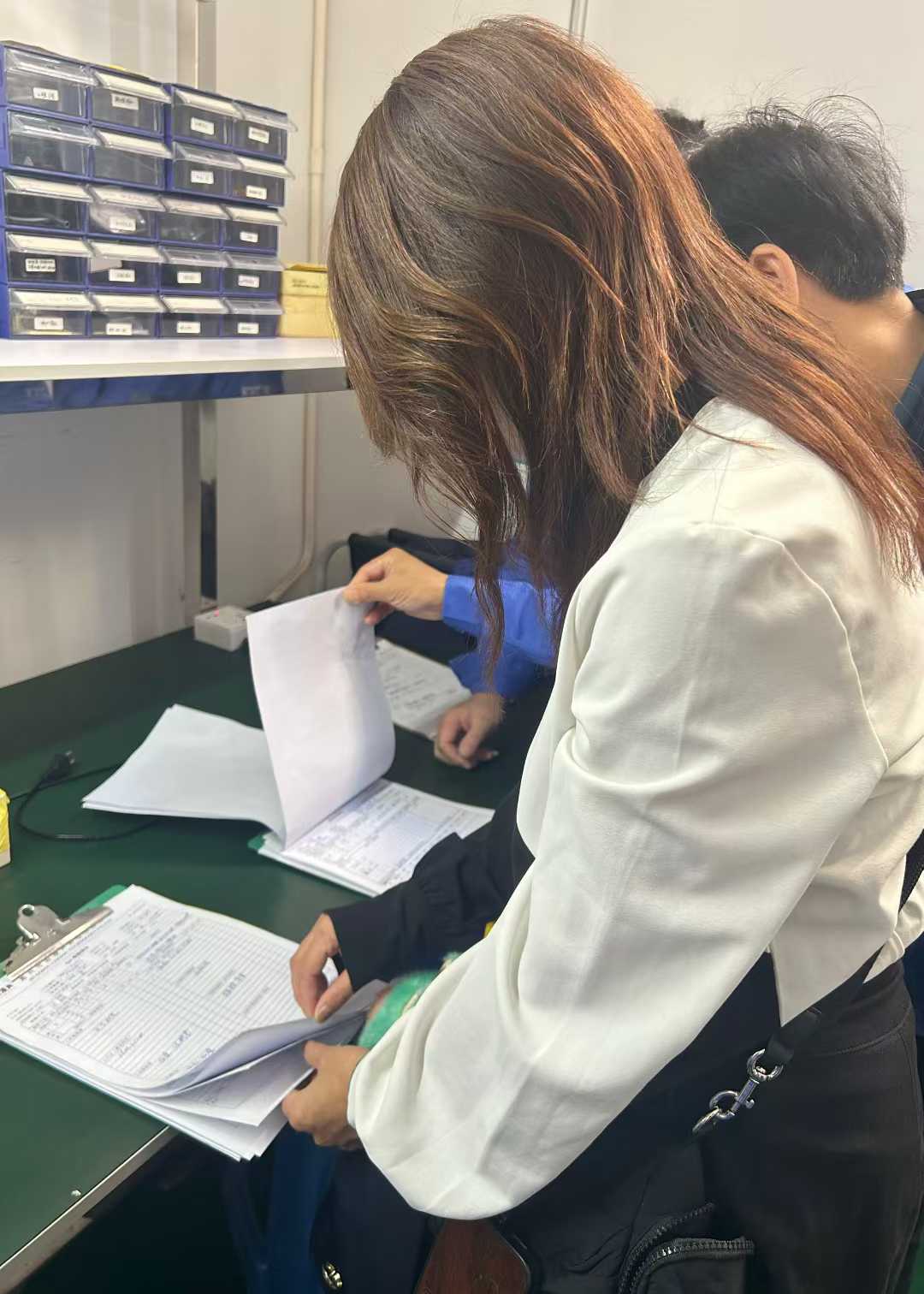

Subsequently, the team drove to the production base in Huizhou. In the workshop, the focus of the audit shifted from "paper standards" to "actual processes". The Japanese experts used sophisticated instruments to randomly inspect the key parameters of the online products; deeply analyzed the operation instructions and process records of core stations such as SMT soldering, unit assembly, and overall machine debugging; and paid particular attention to the real-time and consistency of the unique acoustic characteristic final inspection database of Lirinxin. This non-predefined route and direct approach to key nodes is a true test of the enterprise's daily management level and the resilience of its quality system.

The deeper meaning behind the "second factory visit": Recognition and Expectation

In the context of the reshaping of global supply chains, a renowned Japanese industry giant known for its meticulousness and strictness saw its core QC team visit a Chinese manufacturing enterprise repeatedly in a short period of time. This behavior itself sent out a strong signal.

During the first visit, we witnessed your company's strong hardware capabilities and scale; this time, our aim is to verify the systematic and process-oriented quality assurance capabilities that underpin these hardware. "The person in charge of the Japanese QC team stated during the communication, "From the risk prevention strategies during the R&D stage to every quality control point (QCP) in the production process, we have seen a management system that aligns with the Japanese manufacturing philosophy and is implemented solidly. This full-chain controllability and transparency is the cornerstone for building a long-term trust relationship."

For Li Linxin, this was also a valuable "trial and refinement". The company's general manager stated: "The rigorous reviews by top clients are our best 'quality external auditors'. Every question they raise and every detail they focus on help us view and improve our operational system from a higher and more international perspective. Being able to handle such penetrating audits calmly and gain recognition proves that our 18-year-old path of 'quality first, engineering-driven' is correct."

Build trust through connection and embark together on the future.

The successful completion of this in-depth factory inspection not only paves the way for a potential order, but also represents a solid "capability presentation" by Liminxin Technology on the international high-end manufacturing stage. It demonstrates that Chinese manufacturing enterprises not only can provide production capacity, but also can offer a complete value chain solution from concept to mass production, seamlessly integrating with global top standards.

Win recognition through strength and build trust through professionalism. When the Japanese QC team left with detailed assessment data and satisfactory evaluations, Lirinxin Technology not only received a piece of recognition but also gained a solid bridge leading to deeper and broader international cooperation. This indicates that Lirinxin Technology is steadily integrating into the trust network of the global high-end manufacturing industry with its irreplaceable engineering capabilities and quality beliefs.

Prev: no more

Next: A New Option for In-Ear Monitoring: Focus on Authenticity, Boost Efficiency